Well, the other shoe has fallen. It was another of those little things that you don’t see coming.

I had felt less than my usual strapping self over the weekend and didn’t get much done on the car. On Monday morning I got after it and attacked the front axle beam again. Remember that our goal is to remove the one that had been on the car for the last twenty years and install one that had a ride height adjuster on it. And get every thing else done by Thursday so we could make the practice day on Friday. No pressure…..no, none at all.

I had the second beam all prepared and painted and ready to install. I had even transferred the neat little shock mount brackets.

Removing the old one turned into a bear. I took all the battery tray pieces off the mounting bolts and let it hang. The bottom was pop-riveted to the undertray and I hoped I wouldn’t have to drill it all out and redo every thing there. With the tray dropped down, mostly out of the way, I started on the bolts for the beam itself.

Let me tell you. Bolts that have grown to be twenty years old think well of them selves. They have grown strong and are convinced that since they have been holding things together so long they have acquired tenure and are harder to move than an aging academic. Especially with a little rust and a few coats of paint welding them in place. Time for the convincer.

With a piece of pipe slipped over the end if a socket wrench I had enough leverage to crack the nuts loose and get the removal al started. It took a bit, but finally all the nuts were loose and the bolts came out. The beam still would not budge. I had to go looking again.

I found it. The mounting plate for the master cylinders is a piece of sheet metal which folds ninety degrees from the vertical plane under to form the leading part of the cars belly pan. I think the idea here was that this thicker metal would also protect the driver’s feet should some seriously unfortunate grounding take place. I liked the idea of protecting the driver.

Through this vertical metal plate a series of holes were punched. Three for the barrels of the front and rear brake masters and the third for the cutch master. Above and below each of these are two additional holes where the bolts hold the masters to the plate.

When we tried to move the beam, we could see flexing in the plate and when we looked closer it appeared that the plate was welded to the bottom of the beam. What’s more, it was in an area where you could not get to it to break the welds loose. That was a crusher. It would mean that the entire front end of the car would have to be disassembled in order to remove the beam. Pedal assembles, master cylinders, brake and clutch lines, undertray and everything.

It was already late in the day (did I forget to mention the afternoon rain delay), so with that depressing thought I decided to call it a day and put away my tools.

* * *

I worried over it all night.

I just couldn’t believe that the builders would put something on a car, which could not be dismantled. Especially in an area like the front beam which is prone to damage and likely to need replacement.

So I looked again, and sure enough, hiding behind the front plate was a piece of angle welded to the bottom of the axle beam itself. I guess that someone realized that the plate alone was not strong enough to resist bending from the pressure applied to the brake and clutch pedals. The angle solved that by adding strength at the top of the master cylinder assemblies.

As a mater of fact the top bolts of the masters, all three of them, were attached through the angle. That was why the beam still would not move. Easy enough, undo the top bolts and slide them out. Right. You got to be kidding. They were twenty-year-old bolts, sitting in an awkward position, and not ready to give up the place they called home.

Finally I had them all loose and Hugh and I were able to lift the old beam off the chassis.

With that out of the way I could test fit the new beam. I discovered that the bracket for the ride height adjuster on the lower bar was trying to occupy the same space as one of the master cylinders. Since the lower bracket would not be used it could be cut off and thereby remove the problem. It just takes time.

Of course by this time it was mid day on Tuesday. I realized there was no way to still get the car ready to load on a trailer by Thursday.

On top of that we had promised to help Mike Norton get his car ready for it’s first outing this weekend. The hours just were not working for us.

So we switched gears and started the final preps on Hugh’s car since he was planning to run the practice sessions on Friday.

* * *

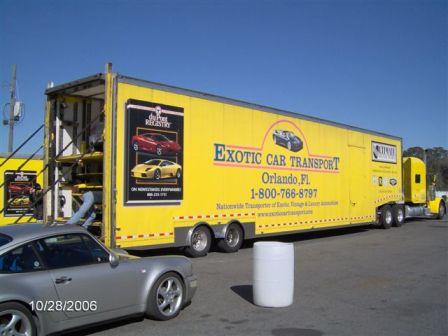

Wednesday afternoon we went out to Mikes and helped him putter with his yellow beast.

He had turned the car over to Brandon to have the new roll bar installed. It would be higher in order to go up over Mike’s head.

Brandon did a nice job but the additional roll bar height and braces meant some adjustment had to be made to the bodywork.

A little work with a sabersaw and we were in business. It looked like Mike would be able to run.

* * *

Wednesday evening we had a nice dinner at Bull’s Corner with Barry and Kathy Bussard, Mike, Hugh and I.

It was our first chance to meet Kathy who turned out to be an attractive and charming lady. She is a little skittish about all this racing stuff but I think she will come around with exposure.

Since we are the only Vee/FST racers at the track we are sort of out own rules committee. Over dinner we had our first unofficial non-meeting. We decided that while we were trying to get the class started we will sort of just run what we have and have a good time with it.

I like that kind of rules.

* * *

Thursday morning we were doing the final prep stuff. Just the usual. Charging the battery. Cleaning up all the dusty and dirty places. Checking the camber settings, installing a new rain light. Checking the new running lights on the trailer. Stuff like that. With luck we would be ready to load the car by lunchtime on. Makes it easy that way.

Wrong.

Last time we went through this process, the starter was bad. This time we didn’t find it until late Thursday morning.

This week’s Judas was the throttle cable. It had frozen solid inside the tube that runs from the Go pedal to the carburetor. It was like someone had poured glue in the tube.

We removed the old cable to use for checking lengths and set out in search of a new cable.

It sounds like a simple thing, but nothing ever is. At our third stop we found something that might work and went home to try it in place.

When it got too dark to see what we were doing when Hugh blew the whistle. Stop for now. He would attack it again in the morning.

I, in turn, would escort Mike to the track and see him through his first practice session. If he was lucky, Hugh would make it out for the afternoon sessions.

We’ll see.